YC hydrocarbon resin C9 YC-130TS Yingcheng Building Materials

Product model:

Still thinking about it? If you want to get a sample first,Please contact us!

Current Product Classification

- Product Description

-

Product Introduction

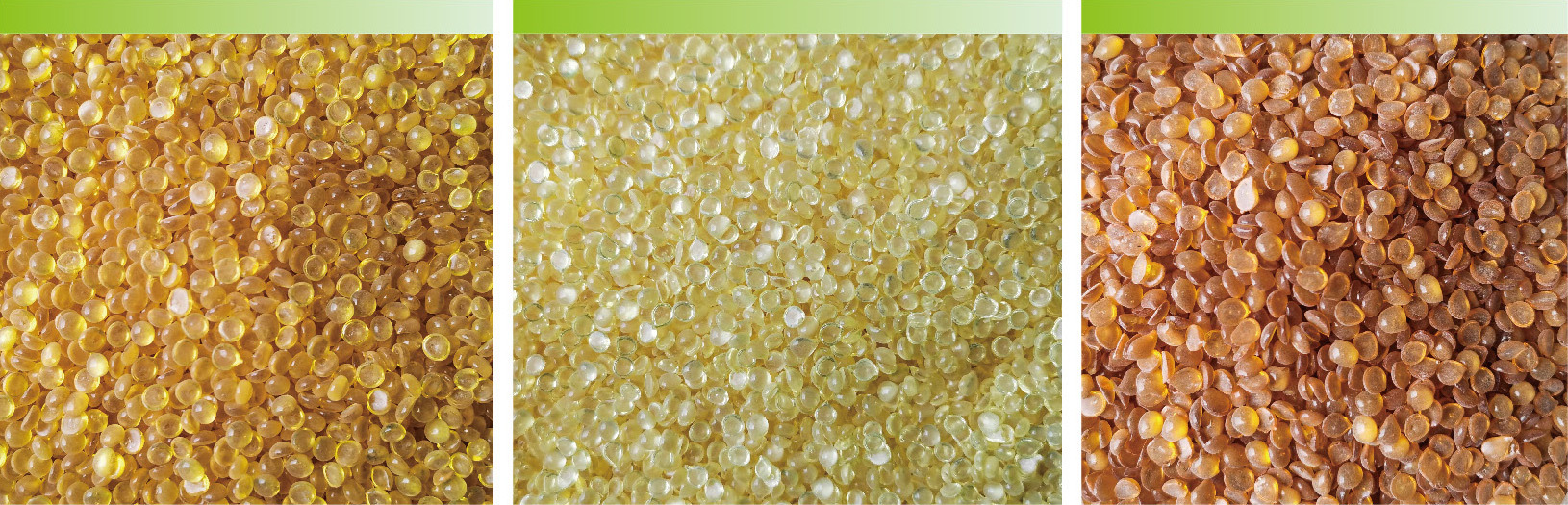

Carbon nine cold poly petroleum resin is through the cracking of C9 raw materials, under the action of catalyst, the formation of carbon positive ion active center, trigger chain polymerization, thus synthetic petroleum resin, it is not a polymer, but molecular weight between 300-3000 oligomers. This product is light yellow granular fixed, it has a low acid value, good miscibility, water resistance, ethanol resistance and chemical resistance and other characteristics, the acid and alkali has chemical stability, and has the characteristics of good adjustment viscosity and thermal stability. C9 petroleum resins are generally not used alone, but are used together as accelerators, regulators, modifiers and other resins.

Product classification and quality indexProject

Detection method

Unit

Scope

Color number (50% resin in toluene)

ASTMD 1544

(Ga.#)

≤13

softening point

ASTME 28

(°C)

130±5

acid value

ASTMD 974

(KOHmg/g)

≤ 0.1

Ash

ASTMD 1063

(%)

≤ 0.1

Specific Gravity

ASTMD 71

1.05-1.10

Packaging and storage

C9 cold poly petroleum resin in indoor storage, and the ambient temperature is not more than 35 ℃, the relative humidity is not more than 85%. This product can be transported by car, ship and train. Pay attention to fire prevention, sun protection, rain prevention and hand protection. The packaging should use 25kg multi-layer composite paper bags or large bags with net weight of 500kg or 1000kg.

C9 cold poly petroleum resin in indoor storage, and the ambient temperature is not more than 35 ℃, the relative humidity is not more than 85%. This product can be transported by car, ship and train. Pay attention to fire prevention, sun protection, rain prevention and hand protection. The packaging should use 25kg multi-layer composite paper bags or large bags with net weight of 500kg or 1000kg.

Product use

This product is mainly used in paint, rubber, adhesive, ink, plastic floor tiles, modified asphalt and other industries additives.

Ink industry

◎ The ink mainly uses C9 petroleum resin with high softening point. The addition of petroleum resin to the ink can play the effect of color development, quick drying, brightening, improve the printing performance and other characteristics, but also can improve the rheology of printing ink and the stability of the connection material, so it is suitable for all kinds of printing ink.

Paint industry

C9 petroleum resin with high softening point is mainly used in paint. This kind of resin can increase the gloss of paint, improve the adhesion, hardness, acid resistance and alkali resistance of paint film. It can be used in the manufacture of road marking paint and antirust paint. It is also widely used in ship paint and alkyd paint.

Adhesive industry

◎ The petroleum resin with a softening point of 100 ℃-130 ℃ mainly replaces the traditional modified rosin and terpene resin, which has good adhesion. Adding petroleum resin to the adhesive and pressure-sensitive tape can improve the adhesion of the adhesive, Acid resistance, alkali resistance and water resistance, and can effectively reduce production costs.

Tyres and rubber products

◎ Tires and rubber mainly use low softening point of C9 petroleum resin, such resins and natural rubber particles have good mutual solubility, there is no big impact on the rubber vulcanization process, tires and rubber added petroleum resin can play a tackifying, reinforcing, softening effect.

Consultation

Note: Please leave your contact information and our professionals will contact you as soon as possible!